Main Switch and HRC Fuses

Main Switch

The Main Switch is a crucial part of a control panel that regulates the flow of electricity entering the panel.

The main switch is the first part the power runs into that connects or disconnects the flow of electrical power in the house. “Mains or Main Switch” is responsible for interrupting or continuing the inflow of power. A number of reasons like lightning strikes, power surges from the utility company, or an overload to the electrical panel could all cause a catastrophe like a spark turning into fire. The switch kills the power supply in case of overload.

It is the first and biggest switch in a circuit breaker (about 60 to 100 amps) and under it or to the side is a row of smaller breakers, maybe 10 or 15 or 20 amps each, that go to each area of the house.

Applications

a) The Main Switch can measure

• Voltage

• Current

• Consumed capacity of the battery connected in the model

• Temperature.

b) Prevents the connectors from sparking when connecting the batteries.

It’s important to know about the location of the main switch, so you can turn it off in an electrical emergency. Some facilities and areas might have more than one main switch. If there is more than one fuse board installed, it is advised to turn on circuits individually after resetting the main breaker.

HRC (High Rupturing Capacity)

A HRC fuse is a part of the circuit that consists of a conductor that melts easily and breaks the connection when the current exceeds the predetermined value.

Definition

HRC fuses (High Rupturing Capacity Fuses) referring to their capability to interrupt high current is a kind of cartridge fuse, where the fuse wire enclosed by the cartridge having good mechanical strength, carries short circuit current in a set period and if a fault occurs in the circuit, it blows off.

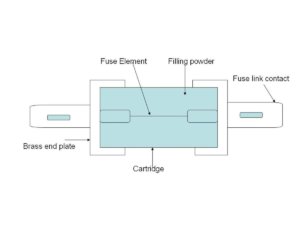

The enclosure or casing of the fuse is tightly shut to avoid atmospheric air. At both sides of the fuse, the ceramic enclosure is made with a metal cap which is welded with fusible silver wire. Its enclosure includes some space surrounding the wire.

Application

• Used for protection of Transformers, Motors, automobiles, etc.

• It is also used in motor stators.

• Backup protection.

Operation:

High Rupturing Capacity (HRC) fuse is an enclosed fuse that is filled with silica sand surrounding the fuse link. (It is used on appliances where the fault current needs to be quenched fast with no spark or fire). In this kind of fuse, the breaking capacity is increased by using two or more separate silver elements in parallel.

Working:

• The flow of current in an electrical network is in a fixed limit and does not break the circuit.

• When current overflows in a fault, a tremendous amount of heat is produced within the fuse.

• When the flow of current has high thermal energy then pieces of equipment that are connected to the network are damaged permanently.

• When the overrated current flows through the HRC fuses, the eutectic element is melted and dissolved in the fuse.

• The filling powder is of such a quantity that the chemical reaction between the silver vapor and the filling powder forms a high electrical resistance substance which very much helps in quenching the arc.

HRC Fuse with Tripping Device.

• When an HRC fuse blows out the tripping device during the fault conditions, it will cause the circuit breaker to operate thus severing the circuit.

• The body of the fuse is made of ceramic material with a metallic cap fixed at each end.

Advantages of HRC Fuse

• During severe faults the HRC fuse breaks the circuit before the peak fault current is reached.

• Inexpensive and economical circuit breaker.

• Avoids the necessity of replacing the fuse (tripping HRC).

• Do not deteriorate with age.

• Low voltage H.R.C fuses are also available in a capacity of 16000A to 30,000A at 400V (Also available in the range of 80kA to 120kA).

• It clears high as well as low fault currents.

• Having high-speed or quick operation.

• Does not explode like the glass fuses under a high current.

• Fusing operation is fast without noise and smoke.

• Capable of handling high as well as low currents.

Disadvantages of H.R.C Fuse:

• Replacement Cost.

• Heat produced by the arc might affect the related switches.

Types of HRC Fuse:

1. NH Fuse

2. Din type

3. Blade contact

NH Fuse

• The NH Fuse is a ceramic-cased rectangular fuse having metallic blade-like terminals on both ends and protection against short circuits and overloads.

• The internal fuse element is attached to the external blades. Mostly these fuses have trip indicators to reveal is the fuse is intact or not.

• These are available in different weights and sizes and the metallic extraction lug facilitates easy removal of the fuse using correct tools.

Din Fuse

• These are accessible in a broad range of rated currents and are used in different fields for different reasons including their feature at different temperature states.

• These are accessible to different levels of voltages and used to protect the transformer. The cleaning capacity of this is excellent for perfect with the short-circuit act.

• These are used in air & mining, feeder sectionalizing, gas-insulated switchgear, and transformers.

Blade Contact

• This type of fuse is also called plug-I or spade. These are available with plastic body & two metal caps to arrange within the socket.

• Generally, these are used in cars to give protection from short circuits, wiring, and used in motors for backup protection.

• These are available in less weight and include less cutoff current.

• Blade type fuses are available in various sizes & shapes along with the capacity of different current ratings.

Known Brands of HRC Fuses

A. Siemens

B. HPL

E. Anchor

Main switches and HRC Fuses fuses are very crucial for the safe functioning of circuits, facilities, and appliances. The correct use and choice of these devices can prevent a catastrophe.

There are a number of choices available in the market to suit your panel. Take expert advice instead of buying a fuse that might not be the best for you. One can buy it from online websites.

(+91) 7439 448 917

(+91) 7439 448 917 Cash on Delivery Available

Cash on Delivery Available

Circuit Breakers

Circuit Breakers Power Distribution

Power Distribution Modular Switchboard

Modular Switchboard Wires & Cables

Wires & Cables