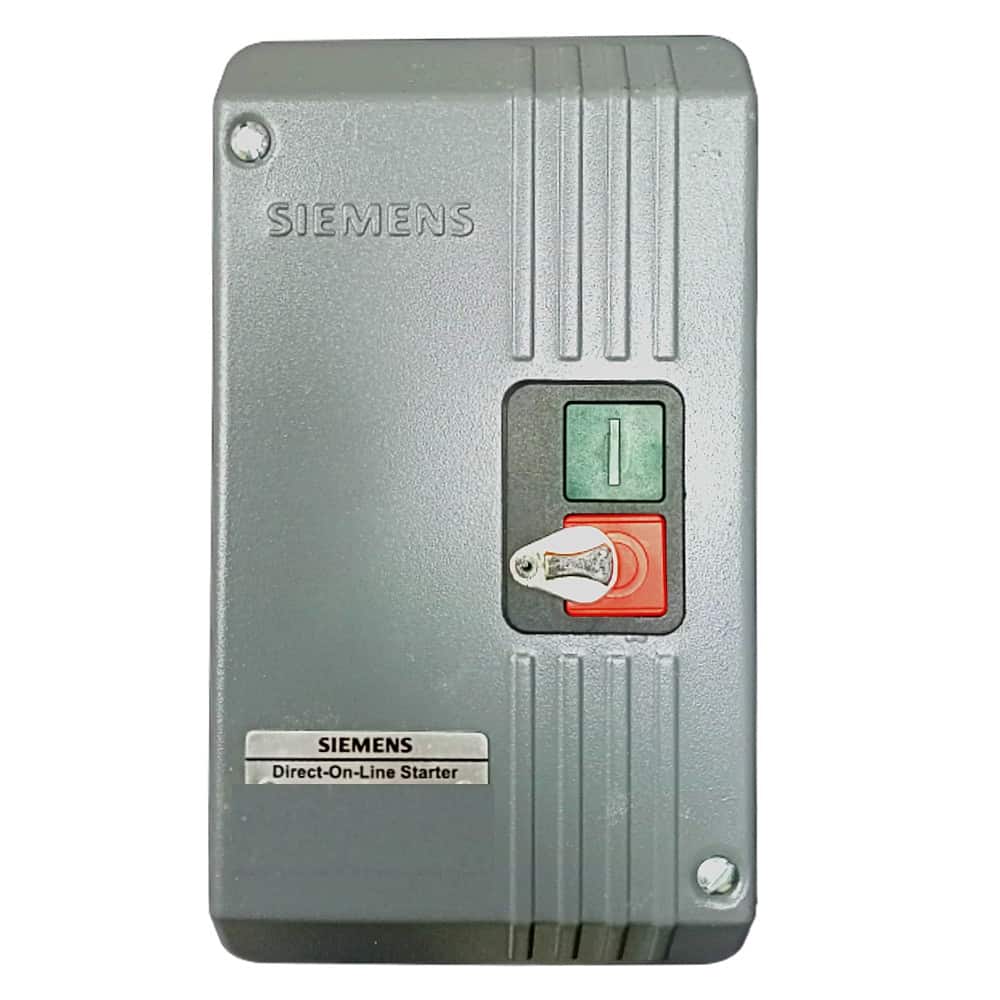

Siemens RAJA DOL Starter Description

Features and Details:

- Starter in sheet steel housing, incl. birelay with SPP

- Motor rating at 415V | 3 phase | 50Hz

Direct On-Line Starter and Its Uses

A DOL (Direct On-Line) Starter is the most fundamental and economical method for running a 3 phase induction motor. The induction motor in DOL Starter is connected directly across its 3-phase supply, and full line voltage is applied by the DOL starter to the motor terminals. Although the connection is direct, the motor is protected from any harm. Apart from protection devices, DOL Starter consists of condition monitoring in some cases.

Construction

In the DOL Starter, there are two switches- Green and Red. The Green switch is for starting and the Red switch is for stopping the motor. For the protection of the motor, there are circuit breakers, overload relay, and contactor. The contacts are controlled by the two switches of the motor. To start the motor, the Green switch is pressed and the full-line voltage starts coming out to the induction motor. In general, the contactors are 3-pole or 4-pole. For example, three normally open contacts and one auxiliary are present in 4-pole type contactors. The normally open contacts connect the induction motor to supply lines and the auxiliary contact is used for boosting the contactor coil when the start switch is pressed. In case of any fault, the holds on the contactor get deactivated and the motor supply is discontinued.

Wiring

The DOL Starter wiring comprises of four parts- main contact, normally open contacts, normally closed contacts, and the connections of the relay coil and the thermal overload relay.

Working

The basis of the working principle in the DOL Starter is the connection to the 3-phase main with the induction motor. The control circuit is energized in any two phases. On pressing the start switch, the current starts flowing through the contactor coil and the control circuit. As the current energizes the contactor coil, a 3-phase supply is available to the motor. Now when we press the stop switch, current stops flowing through the contact, and supply to the induction motor is discontinued. As the supply breaks, the machine comes to rest.

Features of DOL Starter

- High starting current.

- High starting torque.

- Voltages dip in the power mains.

- Simplest controlling mechanism.

- Suitable for low power rated motor.

Advantages of DOL Starter

- Simple and economical to use.

- Comfortable design for design, operation, and control.

- Nearly full starting torque can be provided at the start.

- It occupies less space.

- Troubleshooting is easy as it is not complex.

- The supply is connected to the delta winding of the induction motor.

Disadvantages of DOL Starter

- A high starting current is required (5-8 times of full load current)

- It causes a significant dip in voltage and hence can be used for only small motors.

- The lifespan of the machine is reduced due to the DOL Starter.

- It is mechanically tough.

- The starting torque is unnecessarily high.

Uses

- DOL Starters are best suited for low power rated motors.

- Applied where the starting current poses no threat to the windings of the motor.

- Applied where the starting current does not result in a huge dip in the line voltage.

- For small water pumps.

- For conveyor belts.

- For fans.

- For compressors.

(+91) 7439 448 917

(+91) 7439 448 917 Cash on Delivery Available

Cash on Delivery Available

Circuit Breakers

Circuit Breakers Power Distribution

Power Distribution Modular Switchboard

Modular Switchboard Wires & Cables

Wires & Cables

Reviews

There are no reviews yet